A.V. Vanchikova

RUSARGO Oil sales support technologist

T.A. To the Spirit

Confectionery Development Manager

Concern for the health of the nation contributed to the adoption of the Technical Regulations for oil and fat products of the Russian Federation, which for the first time prescribes requirements for limiting the content of trans-isomers of fatty acids harmful to the human body. But the practical solution to this problem involves the need to change the raw materials used in favor of imported palm oil. Since palm does not grow in our country, the focus should be on the development of those crops that are grown traditionally in Russia, but have qualitatively new properties that allow reducing the content of trans-isomers in food products.

This type of raw material is high oleic sunflower oil (HOO), the production volumes of which are increasing in Russia every year. The main use of high oleic sunflower oil at Rusagro is in frying mixtures produced under the SOLPRO brand.

In order to preserve the nutritional and gustatory qualities and biological value of frying oils during the applied high-temperature food processing, special requirements are imposed on them not only in terms of quality, but also in terms of composition. According to current thinking, the ideal frying oil should be, on the one hand, low in saturation but high in oleic acid (up to 90%) and very low in linolenic acid (no more than 1.0%). When selecting frying oil, an important indicator that characterizes the «safety margin» at high temperatures is the oxidative stability of the oil.

In order to control the quality of frying oil during its use, organoleptic (taste, color, smell) and physical (smoke point, foaming) indicators are evaluated. Important characteristics of the oxidative deterioration processes of fryers are also the free fatty acid content, which in fast food restaurants is monitored using indicator test strips, and the total polar compound content, which is measured by a portable instrument.

Under laboratory conditions, we have the opportunity to further investigate the negative processes in fryer oil by determining acid, peroxide and anisidine numbers.

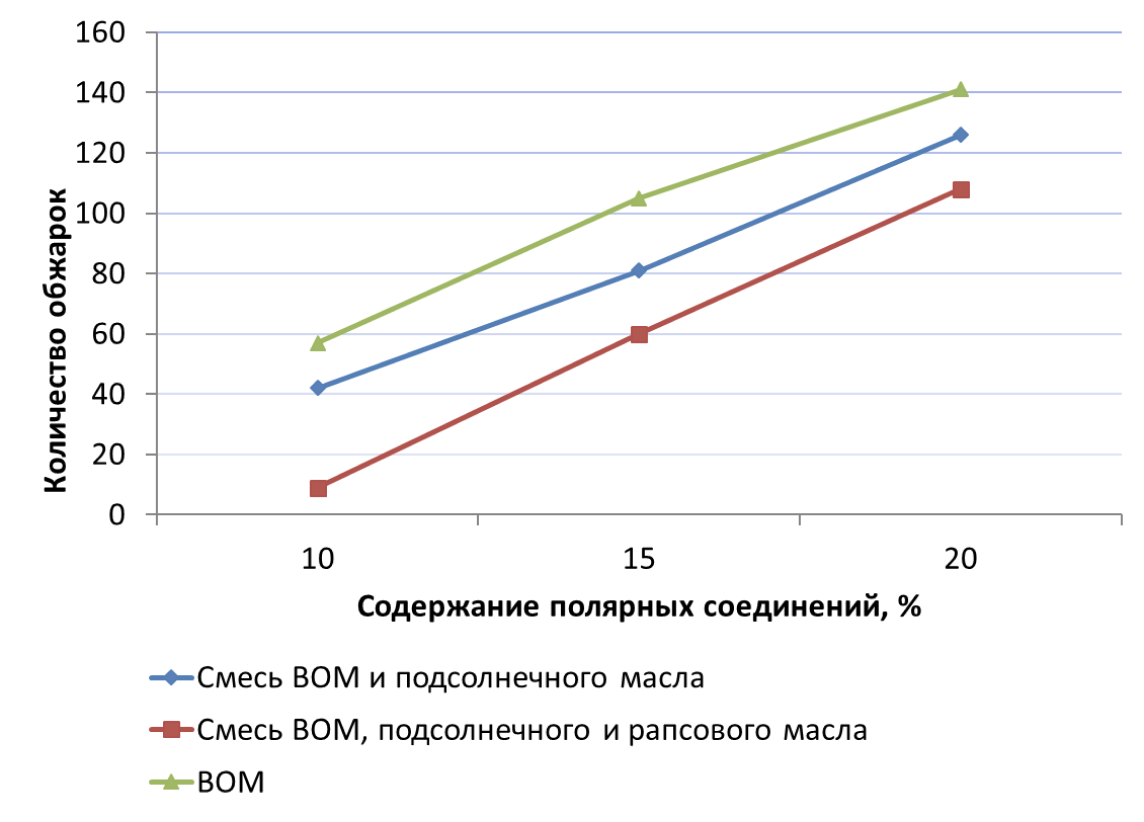

On the basis of the innovation center «RusagroMaslo» in Saratov» comparative testing of liquid natural oils as frying fats in pure form was carried out. Frying of French fries in equal portions (450 g each) at equal intervals was carried out. The temperature of the fryer was maintained at 170-175 °C.

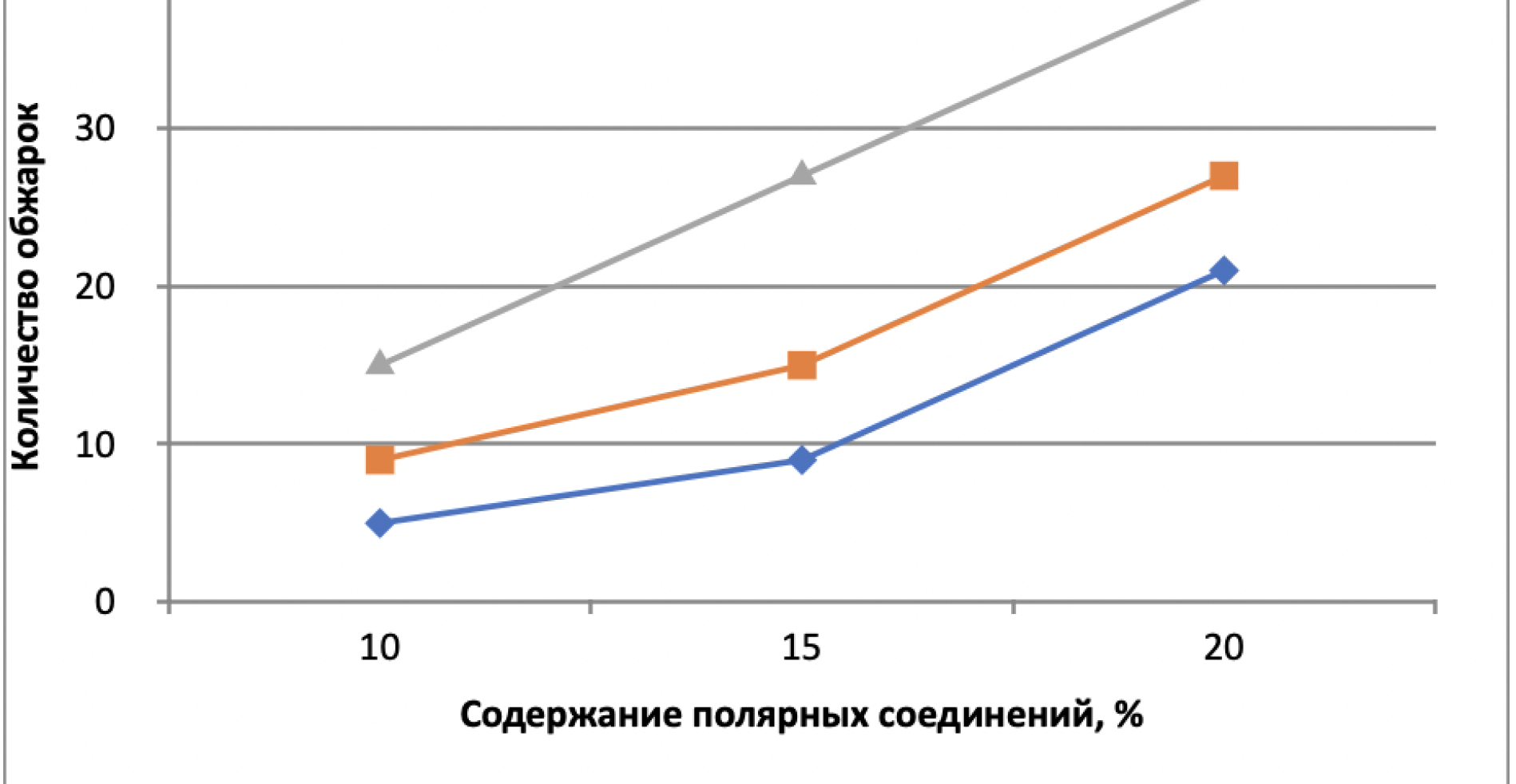

Fig.1 clearly shows the dependence of the «life span» of the fryer depending on the type of oil used. Tests were stopped at a value of 20% polar compounds in the oil. The greatest number of frying without reducing the quality of the fryer and the finished product was achieved with high oleic sunflower oil.

When choosing a fryer mixture, the consumer is focused on the possibility of its maximum long-term use in his production cycle without reducing the quality of the finished product. It is possible to increase the «life» of the fryer due to the natural properties of the oils used in the formulation, as well as with the help of various food additives (defoamers, antioxidants, complexing agents).

At the RusagroMaslo Innovation Center in Saratov, comparative tests of fryer mixtures and PTO were conducted to determine physical and chemical parameters after prolonged temperature exposure. Oxidative stability values of all samples were determined prior to testing.

It can be noted that pure PTO has a significantly higher value than blends. As follows from Table. 1, no significant differences in peroxide and acid numbers were found between the samples.

Two fryer mixtures and high oleic sunflower oil with the food additive E900 were also tested to establish the «life span» of the fryers

Number of servings of potatoes fried to reach 20% polar compounds in a fryer of different composition (with the addition of food additive E 900)

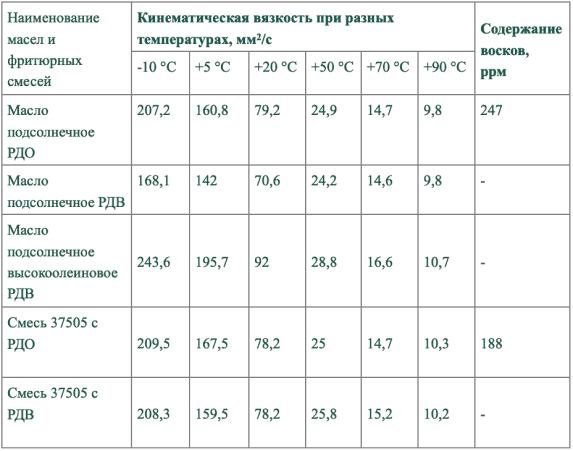

An important parameter of frying oils that affects fat absorption is their viscosity. The viscosity of fat is due to the internal friction between the lipids that make it up. The viscosity of oils is also affected by the content of waxes, which are esters of higher one-atom alcohols and higher fatty acids.

The Innovation Center conducted research on the effect of temperature on the viscosity of various liquid oils and their mixtures. In order to establish the effect of waxes on viscosity, sunflower oil was taken from two types with different degrees of processing — RDO (refined deodorized bleached) and RDV (refined deodorized freeze-dried).

The lower the temperature, the greater the effect of waxes on the viscosity of sunflower oil and the greater the difference between the viscosity values of RDO and RDV sunflower oil. The viscosity of high oleic sunflower oil RDV at 20 °C is almost 23% higher than that of sunflower oil RDV, which is explained by the influence of fatty acid and triglyceride composition of the oils. In blends, the effect of waxes on viscosity is less pronounced because of their lower content. But it can also be assumed that this is the influence of a wider variety of triglyceride composition of the fryer mixture.

100 percent high oleic sunflower oil (HOP)

Two-component mixtures (PTO, sunflower oil) in various packages from 6.9 kg to filling into tank trucks.

Frying oil (sunflower oil and food additives)

Three-component blends (PTO, sunflower oil, rapeseed oil and/or palm olein)